What is Veneer?

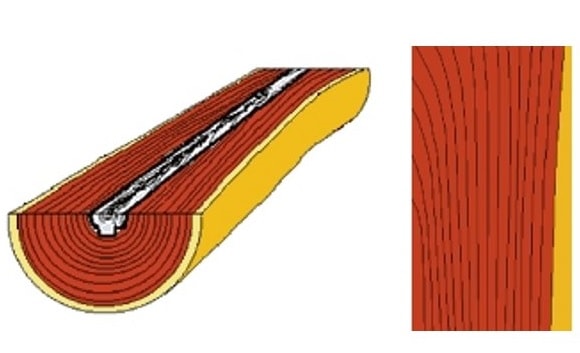

Veneer in simple words is like a covering to plywood. Veneer I would say is one of the 5 most important or prime feature to home interior. Infact veneer is second prime aspect when is come to interiors. Technically, veneer is a thin slice of wood generally 3mm that is glued to on plywood, particle board or MDF. Sometime Veneer can be sliced as thin as 0.5 to 1 mm for better quality and quantity purpose. These thin slices of wood called as veneer are obtained from logs of trees. One can say, with Veneer you next to nature as it is original wood. As is said earlier, Veneer adds to the beauty of furniture of homes.

Types of Veneer

Veneer is available in various wood types like composite veneer, artificial veneer and many more. As a dealer I personally would suggest home owners to choose pure Veneer plywood and not artificial or composite veneer. There are few types of Veneer that serve different purposes like Raw Veneer, Paper-backed Veneer, Phenolic Veneer, Laid-up Veneer, Reconstituted Veneer and Wood on Wood Veneer. There are China made Veneers too easily available in market but the quality will differ a lot.

Decorative veneer of very good quality in India are obtained from tress like maple, walnut, oak tree, mahogany or teak wood.

How is Veneer sheets available to buy?

Veneer are very thin sheets of wood which are difficult to transport. Therefore veneer sheets are glued to a wood sheet at factory level only. Home owners can select a finished veneer sheet of various designs at from dealers of plywood. Carpenters or Interior Designers (whomever home owners have hired) do not have to undergo the headache of getting veneer sheets glued to sheets of wood.

Tips on buying Veneer wood sheets

Veneers calculated in square foot which are grouped in different categories like 16, 20, 22, 24, etc. depending on various style and design. Here the design seen is the grains of tree bark. While Veneer sheets are obtained from tree barks it’s not necessary that the grains of every tree bark be same. It’s a natural thing so the grain style and design will certainly vary. But veneer sheets obtained from a particular tree will have same grain style which are grouped in one category. Similarly veneer obtained from various tress and grouped differently depending on grain design, style and finish.

Now when a home owner is wanting to get furniture done, he shall firstly calculate number of plywood sheets (veneer finished) required to make the furniture of different rooms. This home owners can do with help of carpenters of Interior Designers (whoever he has hired). While at dealers place, Home owners shall buy veneer wood sheets from 1 group to avoid design variation. Also he shall see to it that the dealer is giving from top upper most layer only. This is because many a times the design for lower sheets may vary. Though the difference in veneer design is not much, it’s best to have one design and style veneer woods. If at all there’s a difference, the design can be matched through techniques which still does not give that look and feel. To maintain the look of furniture across house, home owners shall buy veneer from one category only. Infact I suggest home owners to buy and extra sheet of veneer wood on a safer side. Let’s say for a living room, on an average 12 plywood veneer finish sheet are required for furniture. This will incudes- sofa set, TV unit, side table and computer table. Then one shall buy 13 sheets as it can be helpful in future incase of any additions or alterations of furniture.

Leave A Comment